Structural analyst and specialist office ATEC Snamprogetti, Advanced Technologies Department's Pipeline and Technologies Sealine Snamprogetti Fano, group of SAIPEM group.

Project specialist for:

WALKER RIDGE PROJECT – BID

The project includes the development of a steel catenary riser and an oil export pipeline in the oil field at Jack St Malo located between the 759 and 758 block of Walker Ridge Block in Gulf of Mexico. The field was located approximately at 7000 feet (2134 m) of water, discovered at about 270 mi (435 km) southwest of New Orleans.

Particularly involved in:

- Assess the feasibility of installation in S-Lay mode for each section of the project including two oil lines and risers, with the option of two gas lines and the Big Foot project

- Evaluate the installation feasibility of an SCR at the beginning and end of each section of the line

- Assess the feasibility of the line in the event of flooding during installation

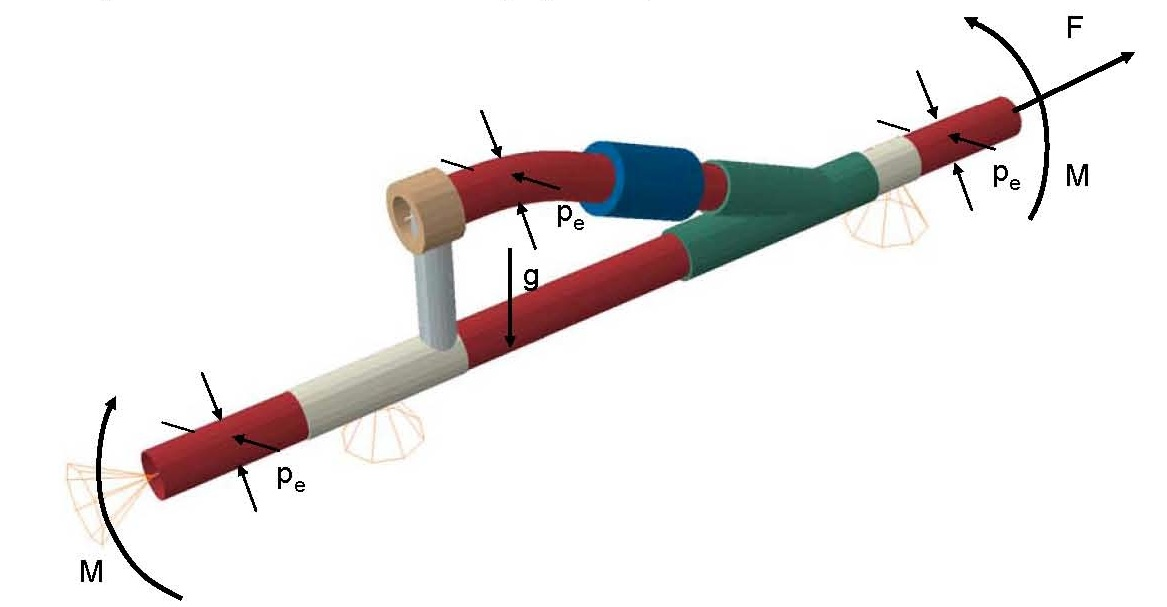

- Assess the installation feasibility for in-line structures, ILS, or valve, ILV, and in particular for the passage through the tensioners, the stinger and along the lay span. Evaluate the installation of a compensation buoy to reduce the stress between the transition pipe-structure and reduce the rotation of the structure

- Evaluate the installation feasibility of a PLET at the beginning and at the end of the line in S-lay mode. In particular, it was studied the feasibility of the passage of the structure through the tensioners, the stinger and along the lay span. Evaluate the installation of a compensation buoy to reduce the stress between the transition pipe-structure and reduce the rotation of the structure.

- Assess the installation feasibility of an in-line structure, ILS, in S-lay mode. The study was performed to evaluate the local stress intensification inside the structure, in particular on the wye.

CLIENT: CHEVRON

- NEW PIPELAYING VESSEL CASTORONE

The goal of the project is to evaluate the feasibility for activities related to the construction of a new pipelay vessel and feasibility to lay the following challenge pipeline in the world. The main projects analyzed were the following: Shtokman, Galsi, South Stream, Iran-India, Sapri-Milazzo, Gorgon, Walker Ridge, Iran to Europe.

The goal of the analysis was related with the following activities:

- Definition the matrix scenarios of the pipeline to be laid by Castorone,

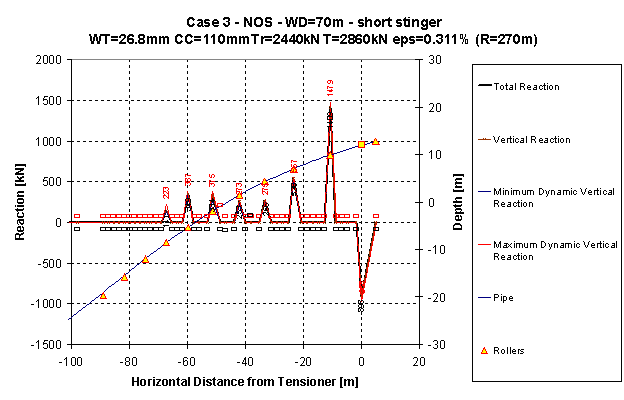

- Static analysis and stinger configuration to lay the pipelines, if feasible,

- Dynamic analysis of the static configurations to determine the maximum allowable sea state of the sea before starting abandonment,

- Assessment of the accidental condition: flooding of the pipeline (wet buckle and / or flooding condition),

- Operability of the vessel in medium and shallow waters,

- Fatigue analysis associated with the installation and in particular with the stress intensity (SIF), stand by and slow lay,

- Evaluation of the operation of abandonment and recovery of the line.

CLIENT: SAIPEM

- NORD STREAM PROJECT

The project includes the construction of two gas lines 48" able to connect Russia to Germany. The two lines have the capacity to provide up to 27.5 bcm per year.

Particularly involved in:

- Mechanical design to define the thickness of pipe, steel and concrete, for each sections of the lines,

- Analyzes related to the installation of two trunklines in each section: the static analyses were performed to define the pipe lay configuration with Castoro SEI and the dynamic analyses to define the maximum allowable sea state accepted for operations;

- Analysis for the installation of buckle arrestors, in particular verify that the stress on steel and cement does not exceed the maximum values allowed,

- Evaluation of the strain intensition factor at the field joint and the transition with the buckle arrestors,

- Static and dynamic analysis for the installation of the lines with the Castoro 10 in shallow water and for the shore approach for approve the feasibility of the operations;

- Verify the feasibility of the above water tie-in vs. the hyperbaric tie-in between two different sections of the line.

CLIENT: NOS

- SOUTH STREAM PROJECT PROJECT - DESIGN

The project includes the installation and construction of a gas pipeline between Russia and Bulgaria.

Particularly involved in:

- Mechanical design for the evaluation of the thickness of the steel along the route;

- Evaluation of the minimum thickness of concrete along the route;

- Assess the need of use of buckle arrestors designing the size in thickness and length.

CLIENT: ENI GAS & POWER

- GORGON PROJECT-INSTALLATION - FEASIBILITY

The project includes the construction of a new gas pipeline in Western Australia.

Particularly involved in the verification for the installation of the pipeline using the pipelay vessel Castorone.

The goal pursued was the following technical activities:

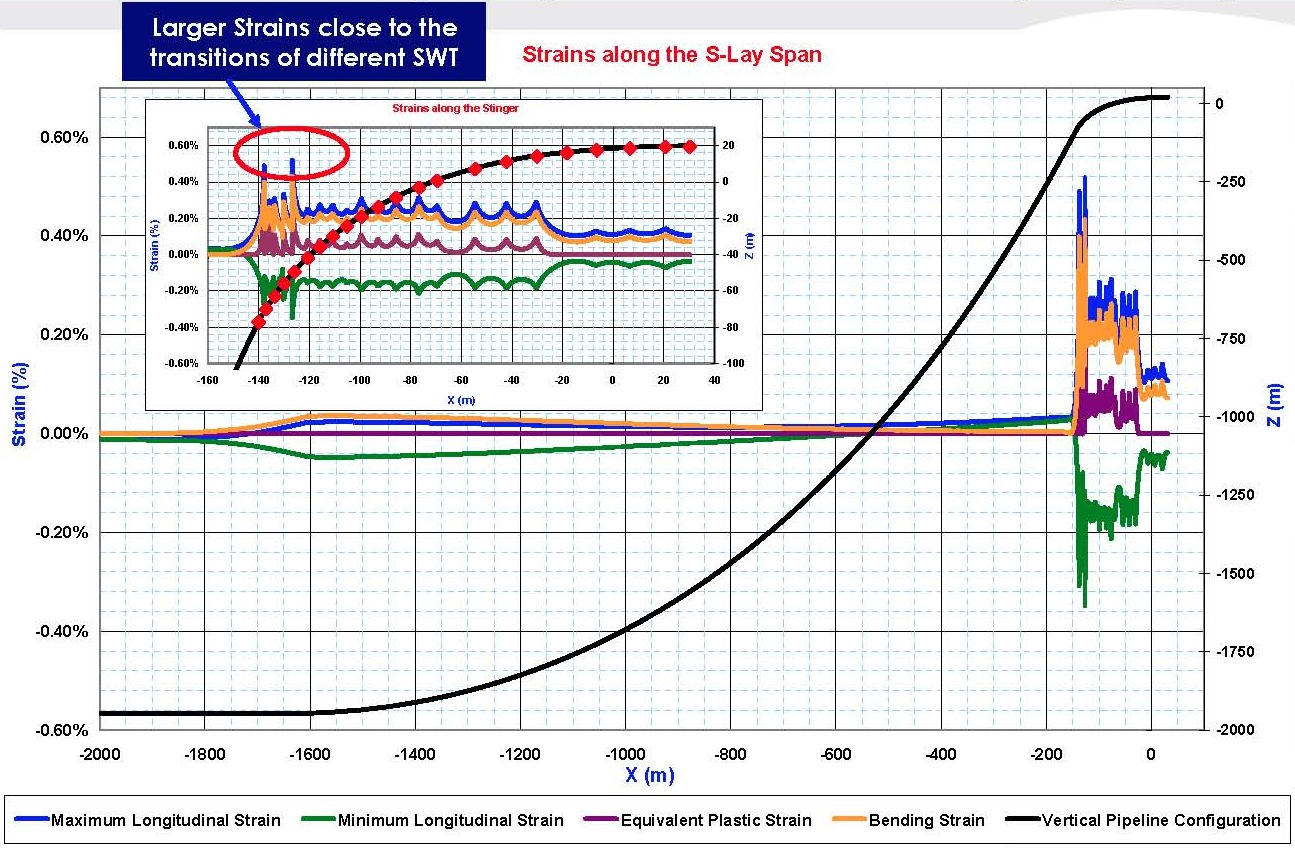

- Static analysis excluding any intensification facto (SIF) to define the roller configuration to lay the pipeline using the pipelay vessel Castorone,

- Static analysis in deep water using the new enhanced DNV criteria instead of the simplified criteria of DNV OS-F101, using the new guideline of DNV.

- Dynamic analysis using all the intensification factor (SIF) induced by concrete and buckle arrestors.

CLIENT: CHEVRON

- BROWSE PROJECT INSTALLATION - FEASIBILITY

The project includes the feasibility for the launch of a line structure for the project Browse in Western Australia.

Particularly involved in the verification of installation of an in line structure using the pipelay vessel Castorone.

The goal was pursued by checking with the project team that the medium can be installed without overtaxing the structure.

CLIENT: WOODSIDE

- SHTOKMAN PROJECT - BID

The project includes the construction and installation of a new pipeline in the Barents Sea.

Particularly involved in the installation feasibilith using the pipelay vessel Castorone.

CLIENT: GAZPROM

- AB 15 GAS GATHERING - BID

The goal of the project was the development of a new gas export line with a new riser.

Involved in the verification activity for the installation and design of a new SHR on Floating Production Storage and Offtake (FPSO) at about 2000m depth in South Africa Eastern offshore Angola.

The goal has been pursued to follow the following technical activities:

- Mechanical check on the riser SHR vs Lazy Wave riser.

- Extreme analysis on the new riser SHR vs Lazy Wave riser connectet into the global system of risers to the FPSO, evaluating possible clashing and analyze the stress during the dynamic.

- Stress analysis of the SHR riser vs Lazy Wave for verification of the allowable sea state

CLIENT: EXXON MOBIL